WASWELL TOC remover: the "pure guardian" of semiconductor ultrapure water system, with TOC value degradation up to 1PPB or less.

In the field of semiconductor manufacturing, the quality of ultrapure water directly affects the performance and yield of chips, and TOC (total organic carbon) content is a key indicator for measuring water quality. The TOC remover, as the core component of the ultrapure water system, shoulders the responsibility of purifying water quality. It can accurately and efficiently degrade organic pollutants in water, using 185nm photocatalytic technology to decompose or remove complex organic compounds, significantly reducing TOC values and ensuring that water quality meets the stringent requirements of semiconductor production. Compared with traditional processing methods, the Huashiwei TOC remover not only has a significant processing effect, but also has strong stability, which can achieve continuous and stable operation, effectively avoiding the problems of wafer surface pollution and uneven etching caused by TOC exceeding the standard. The Huashiwei TOC remover, with its excellent performance, builds a solid defense line for semiconductor ultrapure water systems, helps the semiconductor industry move towards higher precision and higher quality, and is an important guarantee for promoting the development of semiconductor manufacturing technology.

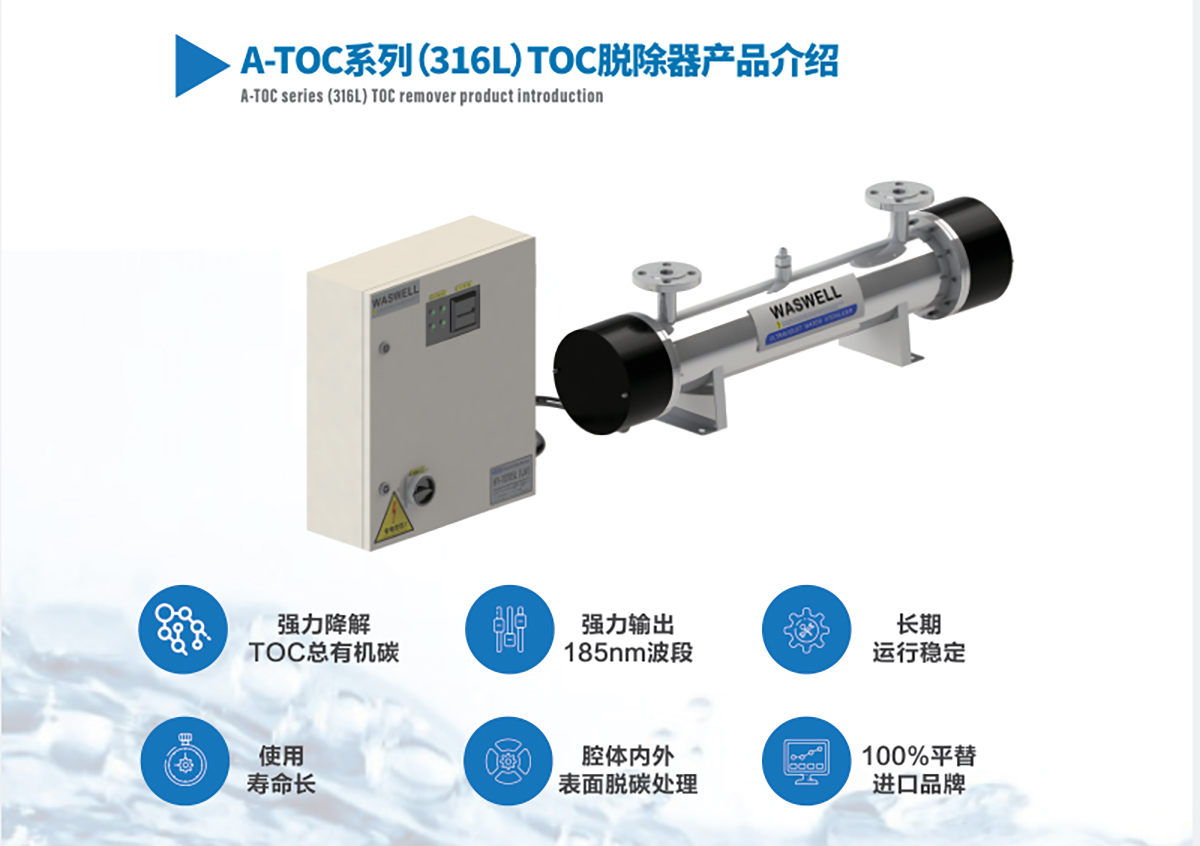

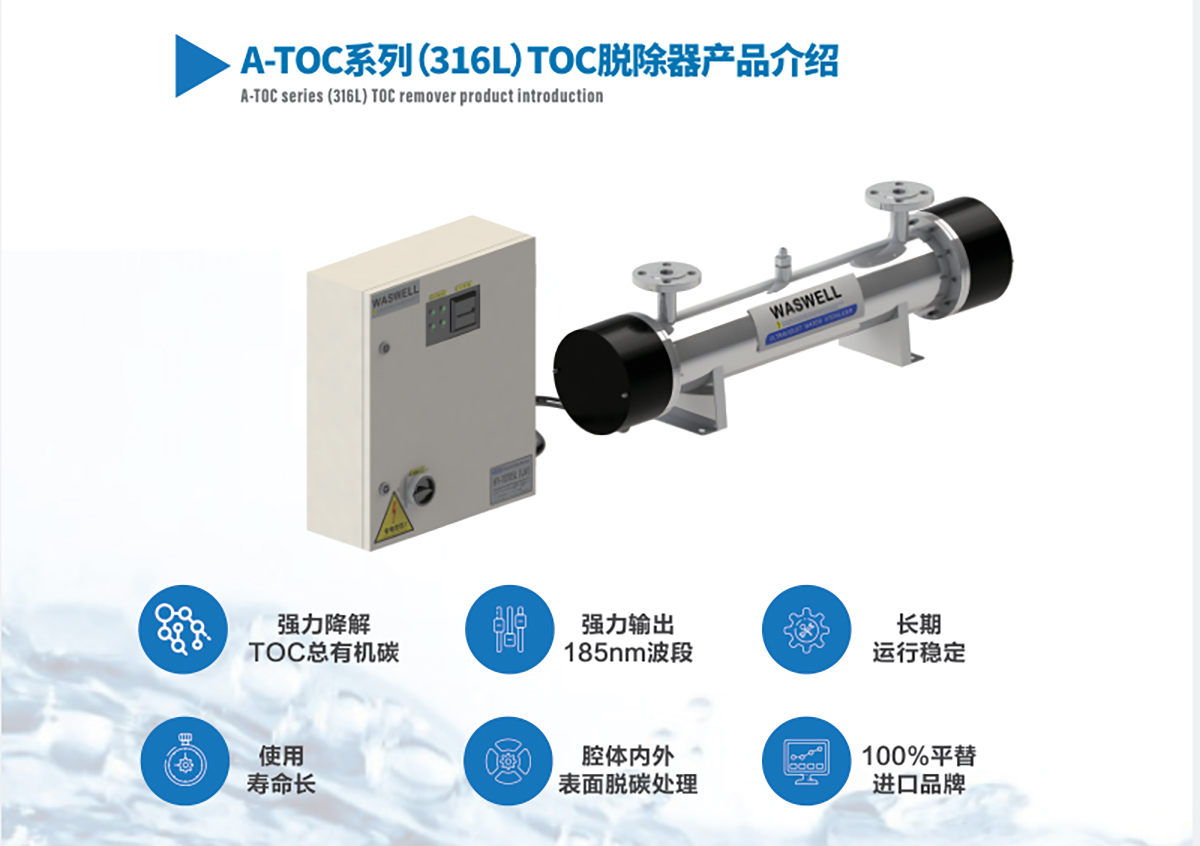

Advantages of Waswelluv TOC remover equipment:

Product advantages:

Small footprint

Optimized UV box design and multiple lamp groups enable cost-effective installation of TOC removal in extremely small spaces.

Components with stable performance

UV sensors, lamps, drivers, and panels have demonstrated excellent reliability in thousands of installations worldwide.

Flexible panel installation

The all stainless steel/carbon steel casing provides the most flexible installation and can be installed in different positions (such as on a UV box or remote location) to meet strict space requirements.

Compact UV box design

With a configurable processing box, it is easy to fit UV systems into narrow spaces and tight pipeline networks. The cylinder can rotate to connect the inlet and outlet at four different angles.

User friendly human-machine interface

By utilizing an intuitive interface, a comprehensive system status check can be achieved. The improved lamp tube technology with low voltage and high output has enhanced the process performance and extended the lifespan of the lamp tube;

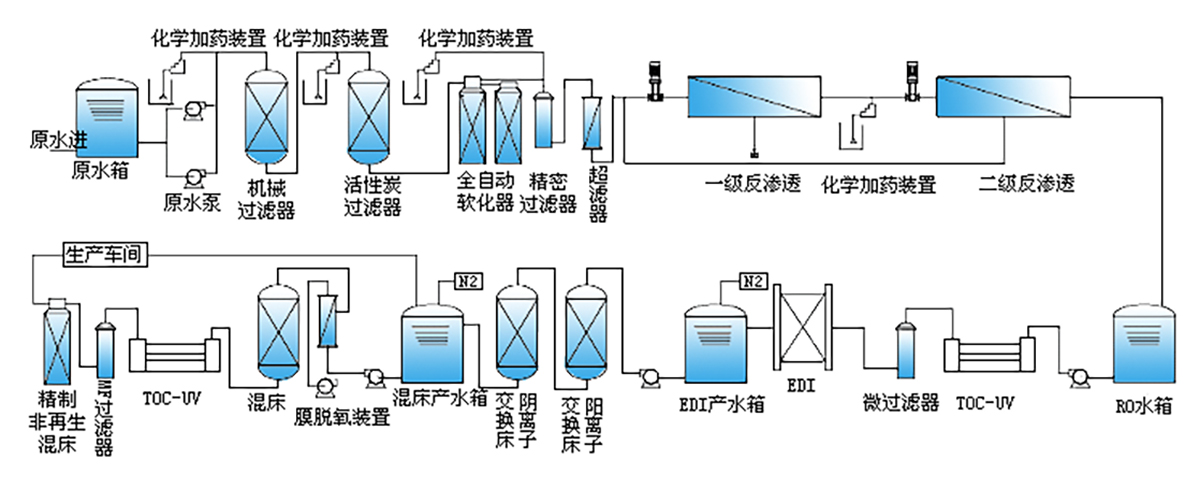

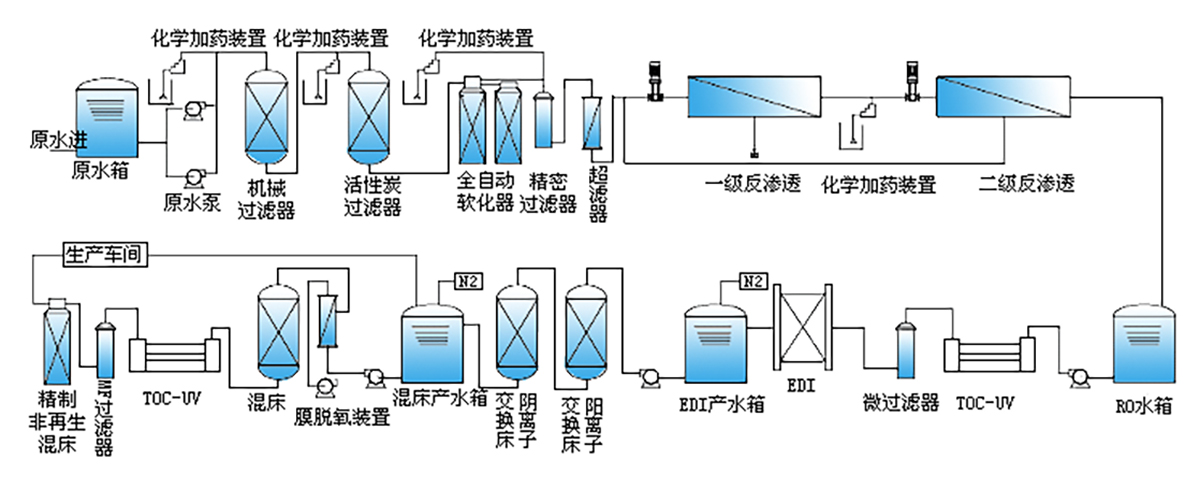

Process flowchart of RO system for producing ultrapure water

WASWELL TOC remover: the "pure guardian" of semiconductor ultrapure water system, with TOC value degradation up to 1PPB or less.

In the field of semiconductor manufacturing, the quality of ultrapure water directly affects the performance and yield of chips, and TOC (total organic carbon) content is a key indicator for measuring water quality. The TOC remover, as the core component of the ultrapure water system, shoulders the responsibility of purifying water quality. It can accurately and efficiently degrade organic pollutants in water, using 185nm photocatalytic technology to decompose or remove complex organic compounds, significantly reducing TOC values and ensuring that water quality meets the stringent requirements of semiconductor production. Compared with traditional processing methods, the Huashiwei TOC remover not only has a significant processing effect, but also has strong stability, which can achieve continuous and stable operation, effectively avoiding the problems of wafer surface pollution and uneven etching caused by TOC exceeding the standard. The Huashiwei TOC remover, with its excellent performance, builds a solid defense line for semiconductor ultrapure water systems, helps the semiconductor industry move towards higher precision and higher quality, and is an important guarantee for promoting the development of semiconductor manufacturing technology.

Advantages of Waswelluv TOC remover equipment:

Product advantages:

Small footprint

Optimized UV box design and multiple lamp groups enable cost-effective installation of TOC removal in extremely small spaces.

Components with stable performance

UV sensors, lamps, drivers, and panels have demonstrated excellent reliability in thousands of installations worldwide.

Flexible panel installation

The all stainless steel/carbon steel casing provides the most flexible installation and can be installed in different positions (such as on a UV box or remote location) to meet strict space requirements.

Compact UV box design

With a configurable processing box, it is easy to fit UV systems into narrow spaces and tight pipeline networks. The cylinder can rotate to connect the inlet and outlet at four different angles.

User friendly human-machine interface

By utilizing an intuitive interface, a comprehensive system status check can be achieved. The improved lamp tube technology with low voltage and high output has enhanced the process performance and extended the lifespan of the lamp tube;

Process flowchart of RO system for producing ultrapure water