WASWELL UV Disinfection Equipment: The 'Health Guardian' of Industrialized Circular Aquaculture

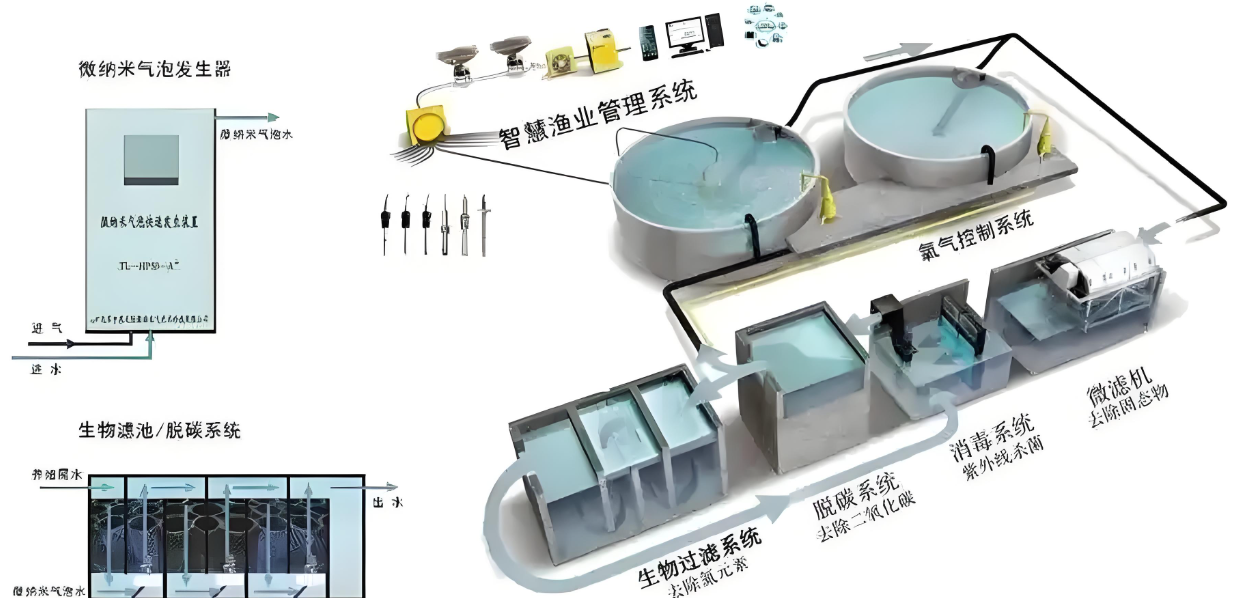

In factory based circular aquaculture, water quality is the key to determining the success or failure of aquaculture, and ultraviolet disinfection technology is the core force in safeguarding water quality. It can quickly and efficiently kill algae, vibrios, sporozoites, fungi, parasites, and various harmful pathogens in water. By disrupting the DNA or RNA structure of microorganisms, it cuts off the transmission routes of diseases from the root. Unlike traditional chemical disinfection, ultraviolet disinfection has no chemical residues, does not affect the ecological balance of water bodies, and does not produce toxic side effects on aquaculture organisms, ensuring the safety and health of aquatic products.

At the same time, this technology is easy to operate, highly automated, and can be seamlessly integrated into the circulating water system to achieve 24-hour real-time disinfection. Its stable and reliable performance effectively reduces breeding risks, improves breeding efficiency, and safeguards the sustainable development of industrialized circular water aquaculture. It is an indispensable technical guarantee for modern and efficient aquaculture.

WASWELL ultraviolet disinfection technology plays a very important role in industrial circulating water aquaculture technology. The ultraviolet disinfection technology is the most green and pollution-free physical disinfection and sterilization technology in the world today. Its advantages are as follows:

1、 Aquaculture water treatment: The Huashiwei ultraviolet disinfection system can be installed in the circulation system of aquaculture water to disinfect the water in real time. It can effectively kill bacteria, viruses, parasites and other pathogens in water, control the spread of aquatic diseases, maintain good water quality, and provide a healthy living environment for aquaculture organisms.

2、 Efficient and broad-spectrum sterilization: Ultraviolet radiation can emit high-intensity, multi wavelength ultraviolet radiation, which can simultaneously destroy the DNA or RNA structures of various microorganisms. It has a good killing effect on various pathogens such as bacteria, viruses, fungi, and algae, with high sterilization efficiency and can achieve a high sterilization rate in a short period of time.

3、 No chemical residues and secondary pollution: Unlike chemical disinfection methods, medium pressure ultraviolet disinfection does not add any chemical agents and does not leave chemical residues in the aquaculture environment, water bodies, or aquaculture products, avoiding the potential harm of chemical substances to aquaculture organisms and the environment, and does not produce secondary pollution.

4、 Stable and reliable operation of equipment: Huashiwei UV disinfection system equipment usually uses high-quality materials and advanced manufacturing processes, with high stability and reliability. The equipment has a long service life and relatively simple maintenance, which reduces the cost of equipment replacement and maintenance for breeding enterprises.

5、 High degree of automation: The Huashiwei UV disinfection system can be equipped with an automated control device, which can achieve functions such as automatic timing switch, UV intensity monitoring, and automatic adjustment according to the needs of aquaculture production. Reduced the workload and errors of manual operations, and improved the accuracy and consistency of the disinfection process.

6、 Strong adaptability: UV disinfection technology has good adaptability to different water quality, water temperature, and water volume, and can maintain stable disinfection effect within a wide range. Whether it is freshwater aquaculture or seawater aquaculture, as well as aquaculture water bodies of different scales, the disinfection needs can be met by reasonably configuring medium pressure ultraviolet disinfection equipment.

影响紫外线对循环水养殖消杀效果的原因如下:

In terms of equipment,

1. Equipment power is insufficient: if the power of the selected ultraviolet equipment does not match the volume and water quality of the aquaculture water body, it will not be able to provide sufficient intensity of ultraviolet radiation, which is difficult to achieve the ideal disinfection and sterilization effect.

2、 Equipment aging: Prolonged use of ultraviolet lamps can lead to aging, resulting in a decrease in ultraviolet output intensity. If the farmers do not replace the aging lamps in time, the disinfection and sterilization effect will be affected.

3、 Improper equipment maintenance: if there is dirt on the surface of the equipment, impurities in the water body accumulate inside the ultraviolet disinfection equipment, etc., it will hinder the transmission and transmission of ultraviolet rays, which will greatly reduce the disinfection and sterilization effect.

Water Body

1. High water turbidity: suspended particles and organic matter in the water will absorb and scatter ultraviolet rays, making it difficult for ultraviolet rays to fully act on pathogens, reducing the disinfection and sterilization effect.

2、 Excessive water flow rate: If the flow rate of water in the ultraviolet disinfection area is too fast, the pathogens in the water flow will not be effectively killed if they are exposed to ultraviolet radiation for too short a time.

Operation

1. Inadequate exposure time: UV disinfection and sterilization water requires a certain action time. If the farmers do not turn on the UV equipment at the specified time, or frequently turn on and off the equipment in a short time, it is difficult to ensure the disinfection and sterilization effect.

2、 Incorrect operation process: for example, the ultraviolet ray equipment is not correctly installed, which makes the ultraviolet ray unable to evenly irradiate the water body, or the operation is not carried out according to the instructions of the equipment, which will also affect the disinfection and sterilization effect.

WASWELL UV Disinfection Equipment: The 'Health Guardian' of Industrialized Circular Aquaculture

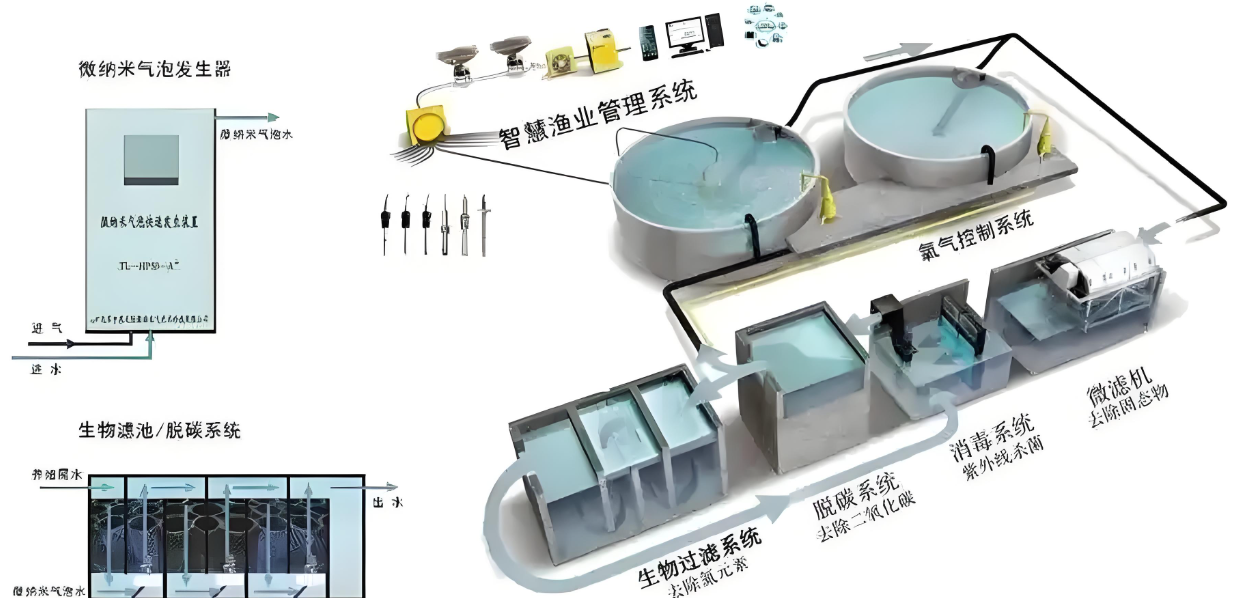

In factory based circular aquaculture, water quality is the key to determining the success or failure of aquaculture, and ultraviolet disinfection technology is the core force in safeguarding water quality. It can quickly and efficiently kill algae, vibrios, sporozoites, fungi, parasites, and various harmful pathogens in water. By disrupting the DNA or RNA structure of microorganisms, it cuts off the transmission routes of diseases from the root. Unlike traditional chemical disinfection, ultraviolet disinfection has no chemical residues, does not affect the ecological balance of water bodies, and does not produce toxic side effects on aquaculture organisms, ensuring the safety and health of aquatic products.

At the same time, this technology is easy to operate, highly automated, and can be seamlessly integrated into the circulating water system to achieve 24-hour real-time disinfection. Its stable and reliable performance effectively reduces breeding risks, improves breeding efficiency, and safeguards the sustainable development of industrialized circular water aquaculture. It is an indispensable technical guarantee for modern and efficient aquaculture.

WASWELL ultraviolet disinfection technology plays a very important role in industrial circulating water aquaculture technology. The ultraviolet disinfection technology is the most green and pollution-free physical disinfection and sterilization technology in the world today. Its advantages are as follows:

1、 Aquaculture water treatment: The Huashiwei ultraviolet disinfection system can be installed in the circulation system of aquaculture water to disinfect the water in real time. It can effectively kill bacteria, viruses, parasites and other pathogens in water, control the spread of aquatic diseases, maintain good water quality, and provide a healthy living environment for aquaculture organisms.

2、 Efficient and broad-spectrum sterilization: Ultraviolet radiation can emit high-intensity, multi wavelength ultraviolet radiation, which can simultaneously destroy the DNA or RNA structures of various microorganisms. It has a good killing effect on various pathogens such as bacteria, viruses, fungi, and algae, with high sterilization efficiency and can achieve a high sterilization rate in a short period of time.

3、 No chemical residues and secondary pollution: Unlike chemical disinfection methods, medium pressure ultraviolet disinfection does not add any chemical agents and does not leave chemical residues in the aquaculture environment, water bodies, or aquaculture products, avoiding the potential harm of chemical substances to aquaculture organisms and the environment, and does not produce secondary pollution.

4、 Stable and reliable operation of equipment: Huashiwei UV disinfection system equipment usually uses high-quality materials and advanced manufacturing processes, with high stability and reliability. The equipment has a long service life and relatively simple maintenance, which reduces the cost of equipment replacement and maintenance for breeding enterprises.

5、 High degree of automation: The Huashiwei UV disinfection system can be equipped with an automated control device, which can achieve functions such as automatic timing switch, UV intensity monitoring, and automatic adjustment according to the needs of aquaculture production. Reduced the workload and errors of manual operations, and improved the accuracy and consistency of the disinfection process.

6、 Strong adaptability: UV disinfection technology has good adaptability to different water quality, water temperature, and water volume, and can maintain stable disinfection effect within a wide range. Whether it is freshwater aquaculture or seawater aquaculture, as well as aquaculture water bodies of different scales, the disinfection needs can be met by reasonably configuring medium pressure ultraviolet disinfection equipment.

影响紫外线对循环水养殖消杀效果的原因如下:

In terms of equipment,

1. Equipment power is insufficient: if the power of the selected ultraviolet equipment does not match the volume and water quality of the aquaculture water body, it will not be able to provide sufficient intensity of ultraviolet radiation, which is difficult to achieve the ideal disinfection and sterilization effect.

2、 Equipment aging: Prolonged use of ultraviolet lamps can lead to aging, resulting in a decrease in ultraviolet output intensity. If the farmers do not replace the aging lamps in time, the disinfection and sterilization effect will be affected.

3、 Improper equipment maintenance: if there is dirt on the surface of the equipment, impurities in the water body accumulate inside the ultraviolet disinfection equipment, etc., it will hinder the transmission and transmission of ultraviolet rays, which will greatly reduce the disinfection and sterilization effect.

Water Body

1. High water turbidity: suspended particles and organic matter in the water will absorb and scatter ultraviolet rays, making it difficult for ultraviolet rays to fully act on pathogens, reducing the disinfection and sterilization effect.

2、 Excessive water flow rate: If the flow rate of water in the ultraviolet disinfection area is too fast, the pathogens in the water flow will not be effectively killed if they are exposed to ultraviolet radiation for too short a time.

Operation

1. Inadequate exposure time: UV disinfection and sterilization water requires a certain action time. If the farmers do not turn on the UV equipment at the specified time, or frequently turn on and off the equipment in a short time, it is difficult to ensure the disinfection and sterilization effect.

2、 Incorrect operation process: for example, the ultraviolet ray equipment is not correctly installed, which makes the ultraviolet ray unable to evenly irradiate the water body, or the operation is not carried out according to the instructions of the equipment, which will also affect the disinfection and sterilization effect.